Variable speed belts are used in mechanical systems where speed control is an important factor. A Variable Speed Belt allows machines to adjust speeds smoothly and efficiently for various applications. These belts are particularly used for power transmission and bear the facility of speed flexibility in operation and machinery making them compulsory in many industries.

What are Variable Speed Belts?

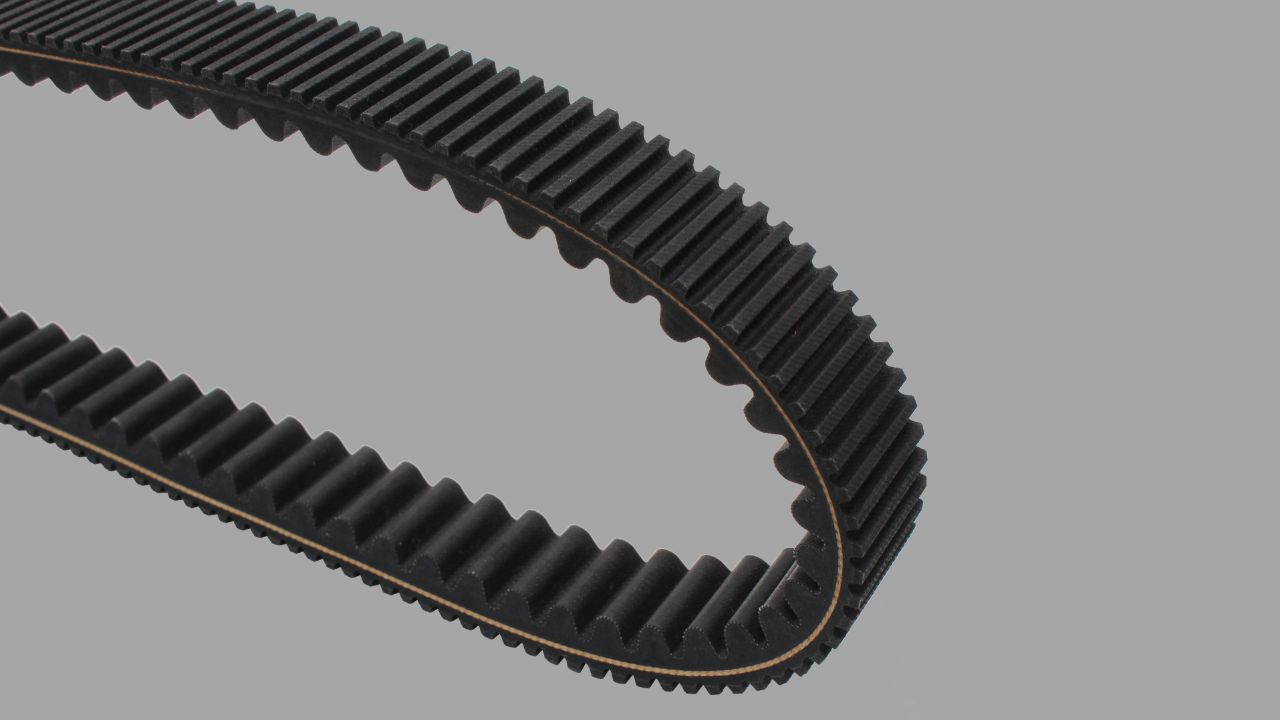

Variable speed belts are belts that are used in drive belt systems that contain pulleys that vary in diameter. Their designs let them change speed ratios in operation; thus, machinery can adopt high or low speeds without stopping or changing components. Often they are manufactured from rather hardwearing materials including rubber or synthetic surfaced rubber containing fiber or metal reinforcements, throughout to provide stiffening, flexibility as well as tear resistance.

Uses of Variable Speed Belts

Stretchable belts are common in many industries because of the flexibility of speed control and performance. Some of their key applications include:

Automotive Industry

In the automotive industry, variable speed belts are used in continuously variable transmissions (CVT). CVTs employ these belts to produce smooth acceleration better fuel economy, and as a result, a better driving experience.

Industrial Machinery

Most of the manufacturing and processing systems use belts whose speeds are variable for equipment such as conveyors, mixers as well as grinders. This flexibility enhances the accuracy and productivity of the production lines.

Agricultural Equipment

Items of agriculture like tractors and harvesters utilize variable speed belts to operate accessories including settlers and balers. This makes it possible to achieve the best performance and energy consumption in different field conditions.

Fitness Equipment

Variable speed belts are used in treadmills and other exercise machines that are found in the gym. They enable users to control the speed and the level of exercise that they want to undertake to meet the user’s fitness needs.

Advantages of Variable Speed Belts

It is for these reasons that variable speed belts are preferred in many applications over and above the flexibility offered by the belts.

Efficient Power Transmission

Variable speed belts are made to slip very little between the pulleys so that there is maximum power transmission. This results in quality performance and minimization of energy wastage.

Durability and Longevity

Constructed from superior materials, variable speed belts have a higher working capacity under conditions such as changes in temperature, heavy loads as well as constant use making them last longer.

Smooth Operation

This kind of transmission system is most appropriate for uses where the change of speed ratios should be continuous. This is especially significant in machinery, which may cause process halts or detriment of parts if the continuity of the energy is interrupted.

Cost-Effectiveness

Thus, variable speed belts do not require other parts or frequent maintenance so as to include speed adjustment in their working scheme – which lowers the operational costs. They also result in reduced time off, thus improving efficiency.

Versatility

These belts are well suited for a vast array of uses, from large Industrial gear, right down to everyday use of products for instance those used in a gym. This makes them a worthwhile investment.

Conclusion

Variable speed belts are one of the most important components in improving the performance and versatility of mechanical systems. These features make them an important component in a wide range of industries where the need for different speeds is possible, as well as their durability and relatively low cost. Explaining both their uses and advantages further illustrates why they continue to be incorporated in today’s industrial and consumer equipment and appliances.