When choosing the best engraving machines for their businesses, industries that use this equipment should consult an expert. To choose the equipment that will produce the best results, the specialists must evaluate the needs of the business. The market is filled with many types of engraving machines, including laser and electronic models. Here are key factors to consider when choosing the right engraving gravure cylinder for your printing needs.

Type of Engraving Machine

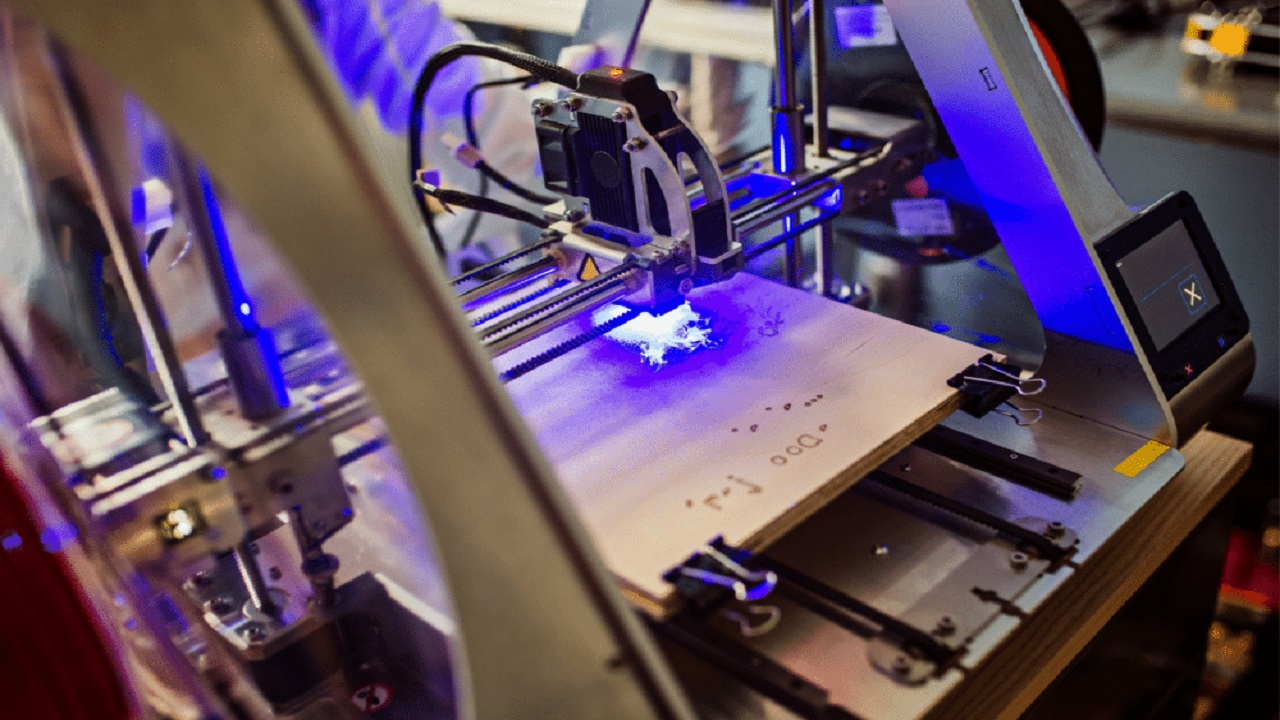

In selecting an engraving machine, experts must determine the category of the machine required by the organization. Because of their extreme accuracy, electronic engraving machines work best for small, delicate prints. However, laser engraving machines work by using laser beams to precisely and without the need for contact draw designs on various materials. Following a needs assessment, the individual can make an informed choice.

Material Compatibility

Material compatibility is very important in this regard. The expert must learn about the type of material in which this machine is used. Metals, rubber, and photopolymers are the best materials for electronic engraving machines, whereas plastics, wood, and acrylics are the best materials for laser engraving machines. To get the greatest results, it is crucial to think about the kind of print plates that will be used and to make sure that the machine is compatible with those types of plates.

Precision and Resolution

The quality of the prints that you get is highly dependent on the precision and efficiency of the engraving machine. Small details and complex patterns cannot be engraved on low-resolution machines. Most of the electronic engraving machines employ a diamond stylus for high accuracy while the new laser engraving machines have high resolution with variable laser rays. Decide on the required resolution of your prints and choose a machine that will offer such a quality.

Production Volume

The volumes of production that an organization requires for their business should be well thought out when selecting an engraving machine. In high-volume production, the machines should be able to handle more items in less time and should have more automated features. Electronic engraving machines may be suitable for high-volume work due to the speed of the machines. Laser engravers also work well in high-production applications because they can perform multiple and varied tasks continuously.

Ease of Use and Maintenance

Select equipment that has simple controls and software that will allow simple engraving to be done. This problem can be solved by products that have clear user manuals and customer support. Also, consider the maintenance equipment that is easy to clean and maintain will be cheaper in the long run.

Budget Considerations

One should try to decide on the budget for the investment as purchasing an engraving machine may seem like a big investment but because of its efficiency and precision, this will be a cost-effective investment in the long run. Determine what is more valuable precision, time, or compatibility with the material. Then, get the machine that offers the most money you are willing to spend. So, a cost-benefit analysis should be done before investing.

Conclusion

Experts should consider the factors when choosing the right engraving machine like the type of engraving machine, compatibility of the material, precision, size, ease of use, and cost. If these aspects are well analyzed, you will be able to choose the right engraving machine that will suit your printing needs and improve your production.